Parts

Center support tube with rivet

Description

This underappreciated part is a vital component of the receiver and assures the precise location of the magazine for reliable operation.

It consists of a hardened and machined center support tube and the rivet that mounts it in the receiver. It has sufficient bending resistance to support and stiffen the receiver in the center section.

A flat machined surface machined on one side precisely locates the magazine at the rear to complete the 4-point suspension of the magazine in the magazine well.

Many aftermarket tubes fail in these vital functions. This is the real military-spec part for a militarily reliable AK.

Part # AKMCST

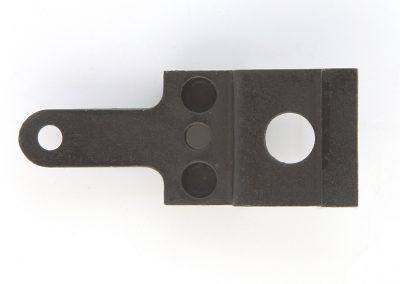

Front trunnion for AKM

Description

The barrel trunnion along with the bolt and the bolt carrier are the heart of the AK system, and the secret of its legendary reliability. This is a true military specification part, made by craftsmen with many years of experience in making this part for military applications.

It is made from the correct mil-spec steel. It is machined precisely to the correct dimensions. It is heat-treated to the correct hardness. It will last many rounds past the expected life cycle of any AK rifle.

This is the classic AKM pattern trunnion, with the cut-a-way reliefs at the barrel pin location—it uses the short barrel pin for the AKM, not the longer one for the AK-47. This is a new part, and has a pilot hole for the barrel pin. The pin hole has not been drilled.

It has the feed ramp riveted in place, and the ramp is the correct feed height for military ammunition.

Do not risk your rifle assembly and your safety with a part that does not have the millions of rounds of military testing behind it. This part will give you the same reliability that is expected from a military-source AK. All of the forces of the cartridge firing are contained in this part. You can use this part with confidence.The trunnuions can be made for 1 mm and 1.6mm receivers.

Part # AKMFT

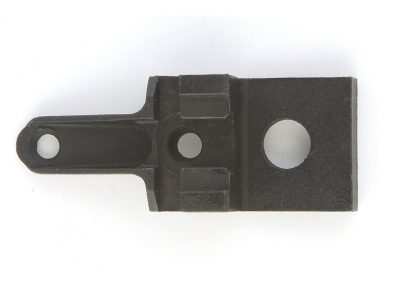

Rear trunnion for AKM

Description

This is the block that is riveted into the sheet-metal AKM or AK-74 receiver to mount the fixed AK buttstock. This is the classic AKM pattern part, mounted with two long rivets that go completely through the receiver and trunnion.

It is correctly machined to retain the recoil assembly and secure the receiver cover at the rear. This part is made from the correct steel and is heat-treated to withstand the battering it receives from the bolt carrier.

Part # AKMRT

Steel butt plate for AKM

Description

This stamped steel buttplate is made for polymer buttstocks as used on the AKM, and is custom made for our polymer stock set. It is precision stamped, heat-treated, and finished a dark blue finish. It has ribs stamped into the back of the plate for stiffness and to increase its grip against the shoulder.

This part meets or exceeds all military standards for resisting damage from using the buttstock as a weapon.

Part # AKMBP

Wood stock set, consisting of stock, lower and upper hand guard

Description

This is a unique wood stock option for the AKM or AK-74. It is precisely machined from beech wood and finished to a beautiful blond color.

The buttstock has a narrower waist than the standard AKM wood buttstock. Its shape closely resembles the polymer buttstock as used on the AK-74. The result is a more natural and comfortable grip when installed. It has a solid steel stamped and ribbed buttplate to meet military specifications. It has the sling swivel mounted on the side to prevent the rifle from twisting when carried on the sling. It has the groove cut in the side as is used on the AK-74.

The lower handguard has a unique shape that mimics the configuration of the AK-74 pattern handguard, but with the grip swells resolved to a diamond shape instead of rounded. It is cut for the steel barrel bushing.

The upper handguard is the standard straight pattern, and is cut for the steel upper handguard spring.

This is a beautiful wood stock set, and is produced to a higher standard than any military -issue set.

Part # AKMWSS

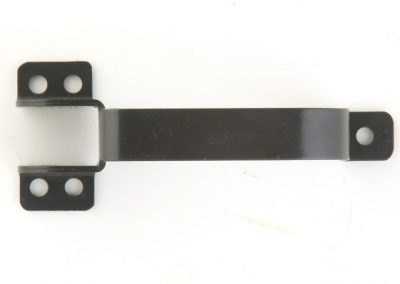

Trigger guard for AKM

Description

Trigger guard for AKM. This is a stamped sheet-metal part as used on the AKM, AK-47, and AK-74. The pattern used is from the AKM. This is a new part, and has not yet been drilled for the magazine catch axis pin. The length of the leg at the front is the correct length for AKM and AK-74 rifles. It can be used with AK-47 but the shape of the trigger guard will be slightly distorted.

Part # AKMTG

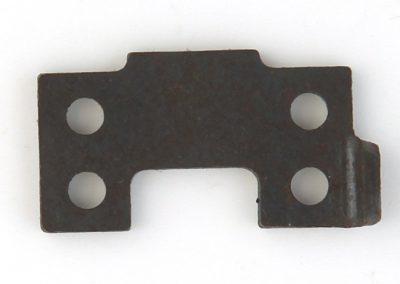

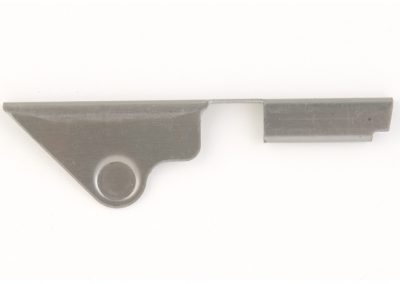

Selector stop for AKM

Description

Selector stop (magazine base) for AKM and AK-74. This is a new, never installed part, and has not yet been machined to correct the receiver height. It will work with AKM and AK-74 rifles. This part does not exist on machined-receiver AK-47 rifles.

Part # AKMSS

Magazine catch for AKM

Description

Magazine catch for AKM, AK-47, and AK-74. This is a new, properly stamped part and is the straight pattern. It does not have the bulge along its length as used in later AKM and AK-74 rifles. It is cut n the back side of the axis pin bore to allow room for the axis pin. When properly installed by the correct machining of the trigger guard and the selector stop, it will hold the magazine firmly up against the bottom of the selector stop to properly position the magazine for reliable feeding of the ammunition.

Part AKMMC

Polymer thumbhole stock for AKM

Description

Made from fiber-reinforced polyamide, with integral ribbed buttplate.

This buttstock was designed to allow the importation of AKs into the United States under the current sporting purposes regulations. It fits standard AKM and AK-74 receivers prepared for fixed buttstocks.

It was designed by a premier AK designer, and is the most ergonomic buttstock ever fitted to an AK rifle. The length of pull is longer to match sporting rifles. When shouldered, It places the rifle in perfect position to align the sights.

While not in any way resembling a military buttstock, in actual use this is one of the most natural and comfortable buttstocks ever made. It is attractive enough to grace any sporting-grade rifle.

Part # AKMPTS

Polymer stock set for AKM, consisting of stock, upper and lower hand guard, and pistol grip

Description

These parts are made from black fiber-reinforced polyamide. This set is superficially similar to the polymer set as used on the military AK-74. Designed by a premier AK designer, it is a clear evolutionary improvement over the military set. It uses substantially more material to increase its strength and durability. Each piece has improvements over the original design. See individual parts descriptions for details.

The lower handguard has a polished stainless steel heat shield. The upper handguard is vented to release heat and allow installation of a rail. The handguards fit flush together—the heat goes up, not outward between the handguard to prevent burning of the hands. The pistol grip has sharp checkering and has improvements to hold it securely on the grip screw nut.

Buttstock for AKM and AK-74

Description

This buttstock is made from black high-strength fiber-reinforced polyamide. The buttstock has a much larger radius on the top to increase comfort under recoil. The military version is quite sharp at this point, and can dig into the cheek under the recoil of the rifle. The thickness is also increased at this point to allow a cheekpiece to be installed with screws. The buttplate is solid stamped steel with stamped-in ribbing. The sling swivel is on the side to prevent the rifle from twisting when carried on the sling.

The buttstock has the horizontal groove as used on the AK-74. It is substantially stronger than the military polymer buttstock, and will withstand any military use as a secondary weapon.

Part # AKMPSS

Polymer lower handguard for AKM

Description

This lower handguard is made from black fiber-reinforced polyamide, and has a polished stainless steel heat shield mounted with screw fasteners. The shape is very attractive, and the swells for hand grip at the bottom are diamond shaped for a better grip. There is a metal lug molded in at the front to securely engage the forward flange on the rifle.

The heat shield has a vertical projection at the front that is used to tune the barrel for optimum accuracy. It is sized for AKM-pattern rifles, and can be easily machined to fit thicker AK-47 pattern rifles.

It mounts flush with the upper handguard to prevent hot gas from escaping between the handguards during extended firing. Ventilation is achieved through holes in the upper handguard.

The mounting lugs at the rear that go into the receiver are full height for AKM and AK-74 receivers. They can easily be shortened to fit AK-47 pattern machined receivers.

Part # AKMLHG

Polymer upper handguard for AKM

Description

This part is molded from high-strength black fiber-reinforced polyamide. It fits any standard AK gas tube, including AKM, AK-74, and AK-47. The unique design has vent holes on the top to allow heat to escape from the top. These holes can also be used to mount a rail on the handguard.

This design allows the handguard to be mounted tightly against the lower handguard to prevent heat from escaping from the joint between the handguards. This prevents heat from extended firing causing burns or discomforts to the shooter during extended firing.

To facilitate precise fitting with no looseness or rocking possibility, there are small lugs protruding on the bottom to allow precise fitting by an armorer when assembling. This allows precise fitting of the handguard to ensure level installation when using a rail.

Part # AKMUHG

Polymer pistol grip for AKM

Description

This part is molded from black fiber-reinforced polyamide. It has sharp checkering and a textured surface for enhanced gripping. It fits all standard AK-pattern rifles including AKM, AK-74 and AK-47.

It has an integral reinforcement surface at the bottom to secure the grip screw nut without the need for a metal ferrule, and is precisely molded at the top to engage the grip screw nut and prevent turning or twisting after installation.

It has been carefully designed to fit comfortably in the hand.

Part # AKM??

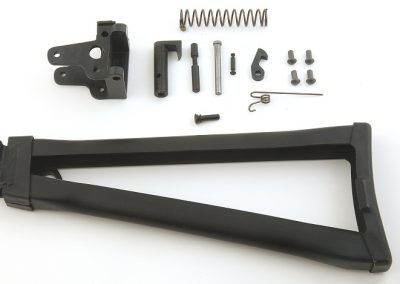

Metal side folding stock for AK 74

Description

Side-folding buttstock set from the AKS-74U and AKS-74. This is the only standard buttstock for the AK-pattern rifles that folds to the left placing the buttstock out of the way of the selector lever when folded. The set consists of the sheet-metal buttstock, the rear trunnion for mounting in the rear of the receivers, the latching parts for the trunnion, and the latch for the front of the receiver that secures the buttstock in the folded position. All necessary springs and pins are included. This stock set can be mounted during the assembly of new rifles, or can be installed on existing rifles by removing the existing rear trunnion and doing some machining on the standard receiver. This is the Bulgarian pattern of the buttstock with the same size pivot pin and pivot hole in the buttstock. The pin is 5.5 mm.

Part # AK74SFS

Receiver blank for AKM for 1.6 mm

Description

When Mikhail Kalashnikov designed the AKM with its sheetmetal receiver to replace the machined-receiver AK-47 he had two important goals that affected the design of the new receiver.

First, he wanted to retain as much parts interchangeability with the AK-47 as possible. Second, he was very focused on reducing the weight of the finished rifle.

The finished wall thickness of the machined receiver is 1.6mm. Also, the thickness of the top rail and the thickness of the ejector on the machined receiver is 1.6mm. A 1.6mm sheetmetal receiver would keep these critical dimensions the same and ensure that the bolt carrier, the bolt, the selector lever, and the axis pin designs could continue to be used with the new AKM rifle.

However, the use of the thicker receiver sheetmetal would increase the weight of the receiver shell by over 100 grams. In the design of the AKM, many machining steps were introduced that reduced part weight by a few grams. He could not accept the extra weight of the thicker shell. He adapted a 1mm thick sheetmetal, and incorporated some details that allowed the 1mm sheetmetal to effectively have the 1.6mm thickness he needed to fit the earlier parts designs. Some of these include

- The “step down” deformation on the top rail. When measured from the bottom of the deformation to the upper surface of the receiver, this dimension measures 1.6mm, giving the correct 1mm total clearance inside the 2.6mm slot in the bolt carrier.

- The deformations (“chickenfeeet”) on the side of the receiver where the axis pin heads go through the receiver. The groove in the axis pin for the retaining spring holds the pin 1.6mm from the outside of the sheetmetal. The measured depth from the outside of the receiver to the inside of the deformations is 1.6mm, ensuring that the axis pins are flush with the side of the 1mm receiver.

- The left rail welded into the receiver is 1.6mm thick to give the correct clearance of the bolt slot as it passes over the ejector to eject the spent cartridge. To same weight, the right rail is 1mm thick sheetmetal.

The Chinese and the Serbians went a different route. They used the thicker sheetmetal and did not have to make the adaptations for the thinner metal.

In comparing rifles made with 1mm metal and 1.6mm metal, several things are immediately apparent.

- The action of the bolt carrier as it travels over the rails is much smoother on the 1.6mm thick receivers. It feels much like the action of a machined receiver AK-47.

- The feeling of the rifle when fired is quite different. The recoil is basically straight back, with no noticeable deformation of the receiver. This sensation is very noticeable when firing 1mm and 1.6mm receiver AKMs side by side. The sensation is very similar to firing a machined receiver rifle.

- The weight is more than a standard 1mm AKM, but noticeably lighter than a traditional AK-47.

For comparable levels of quality and manufacturing, a rifle with a 1.6mm receiver will also be more accurate than a comparable rifle with a 1mm receiver.

To capture these advantages, we offer a sheetmetal AKM receiver made with 1.6mm mil-spec steel.

This is the sheetmetal receiver blank after all stamping and folding operations are complete. It is made from the correct steel to allow precise stamping and hardening to the correct military specifications. The thickness is a true metric 1.6mm, not an approximation.

Producing the receiver to this stage requires expensive precision dies and large expensive stamping equipment. With these processes already done, all that is needed for completing the receiver is heat-treating equipment and standard machine shop equipment.

It requires heat-treating and final machining to complete into a finished AKM receiver. It has the following features:

- This is a bent shell, not a flat. It is completely stamped, ready for further processing.

- Trigger guard opening are complete, including grip nut opening and rivet holes.

- Magazine well opening is stamped, but is undersized to allow precise machining to final dimensions. The opening is narrow enough to machine for 7.62 and 5.45 magazine width.

- Magazine dimples on the side of the receivers are stamped.

- Magazine ramp on bottom is complete.

- Top rails are bent in full length, ready to machine to AKM or AK-74 configurations. Because the metal is already 1.6mm thick, there is no need for the “step down” feature.

- The wall thickness is 1.6mm, so there is no need for deformations at the axis pin locations.

- Length is correct to mount trunnions with no trimming or machining required.

- No rivet holes are stamped, so the receiver can be machined for fixed stock, underfolding stock, or sidefolding stock as desired.

- The trigger axis holes are not stamped in place. This allows precise machining after heat treating to ensure these critical dimensions are correct in the finished receiver.

This is a true universal 1.6mm receiver blank, ready to process into a military specification receiver for AKM or AK-74. Having the shell complete to this stage greatly simplifies the tooling required for an AK manufacturing operation. This is a true mil-spec no compromise base for producing the most rugged, reliable military receiver ever produced.

Part # AKMR – 1.6

1 mm Receiver blank for AKM

Description

This is the sheetmetal receiver blank after all stamping and folding operations are complete. It is made from the correct steel to allow precise stamping and hardening to the correct military specifications. The thickness is a true metric 1mm, not an approximation. This means parts that require this thickness for precise fitting will function properly.

Producing the receiver to this stage requires expensive precision dies and large expensive stamping equipment. With these processes already done, all that is needed for completing the receiver is heat-treating equipment and standard machine shop equipment.

It requires heat-treating and final machining to complete into a finished AKM receiver. It has the following features:

- This is a bent shell, not a flat. It is completely stamped, ready for further processing.

- Trigger guard opening are complete, including grip nut opening and rivet holes.

- Magazine well opening is stamped, but is undersized to allow precise machining to final dimensions. The opening is narrow enough to machine for 7.62 and 5.45 magazine width.

- Magazine dimples on the side of the receivers are stamped.

- Magazine ramp on bottom is complete.

- The deformations on the side of the receiver at the axis pin locations are stamped in.

- Top rails are bent in full length, ready to machine to AKM or AK-74 configurations. The “step-down” is stamped in place for proper fitting of the bolt carrier on the rails.

- Length is correct to mount trunnions with no trimming or machining required.

- No rivet holes are stamped, so the receiver can be machined for fixed stock, underfolding stock, or sidefolding stock as desired.

- The trigger axis holes are not stamped in place. This allows precise machining after heat treating to ensure these critical dimensions are correct in the finished receiver.

This is a true universal 1mm receiver blank, ready to process into a military specification receiver for AKM or AK-74. Having the shell complete to this stage greatly simplifies the tooling required for an AK manufacturing operation. This is a true mil-spec no compromise base for producing the most rugged, reliable military receiver ever produced.

Part # AKMR- 1.00

Left bolt rail for AKM

Description

This is the standard left-side bolt rail, ready to be welded into an AKM receiver. It is 1.6mm thick and made from the correct steel. It is precision stamped, and is compatible with semi-auto and full-auto actions.

It is long enough for 5.45×39 caliber rifles and can be machined to the correct length for 7.62×39 rifles in the top rail machining process. It has the correct projection on the front to be machined to a precise fit for either 7.62×39 or 6.56×39 magazines, allowing the four-point suspension that contributes the legendary reliability of the AK rifle.

Part # AKMLBR

Right bolt rail for AKM

Description

This is the standard right-side bolt rail, ready to be welded into an AKM receiver. It is 1mm thick, and is made from the correct steel. It is precision stamped, and is compatible with semi-auto and full-auto actions. It has the correct projection on the front to be machined to a precise fit for either 7.62×39 or 6.56×39 magazines, allowing the four-point suspension that contributes the legendary reliability of the AK rifle.

Part # AKMRBR

Rivet set of each for AKM

Description

These are correct rivets for assembling a military-grade AK-74 rifle. They are the correct diameter for properly filling the holes when bucked, and are the correct hardness to allow bucking but still hard enough to prevent cutting from the action of the rifle. The heads are the proper shape to give the correct look to the finished receiver.

The set consists of rivets, one long rivet and two short rivets for the rear trunnion, four short rivets for the trigger guard along with on extra-short rivet for the front of the guard, and 6 short rivets for the barrel trunnion. One extra rivet is included as a spare.

Part # AK74RS

Plastic handle for Makarov pistol

Description

This is the standard military pistol grip for Makarovs and fits standard models made anywhere in the world. It is made from durable black plastic, and mounts with the standard military grip screw.

It is ergonomically shaped to enhance grip and reduce felt recoil.

Restore your civilian Makarov to the correct military appearance with this part.

Part # MPH